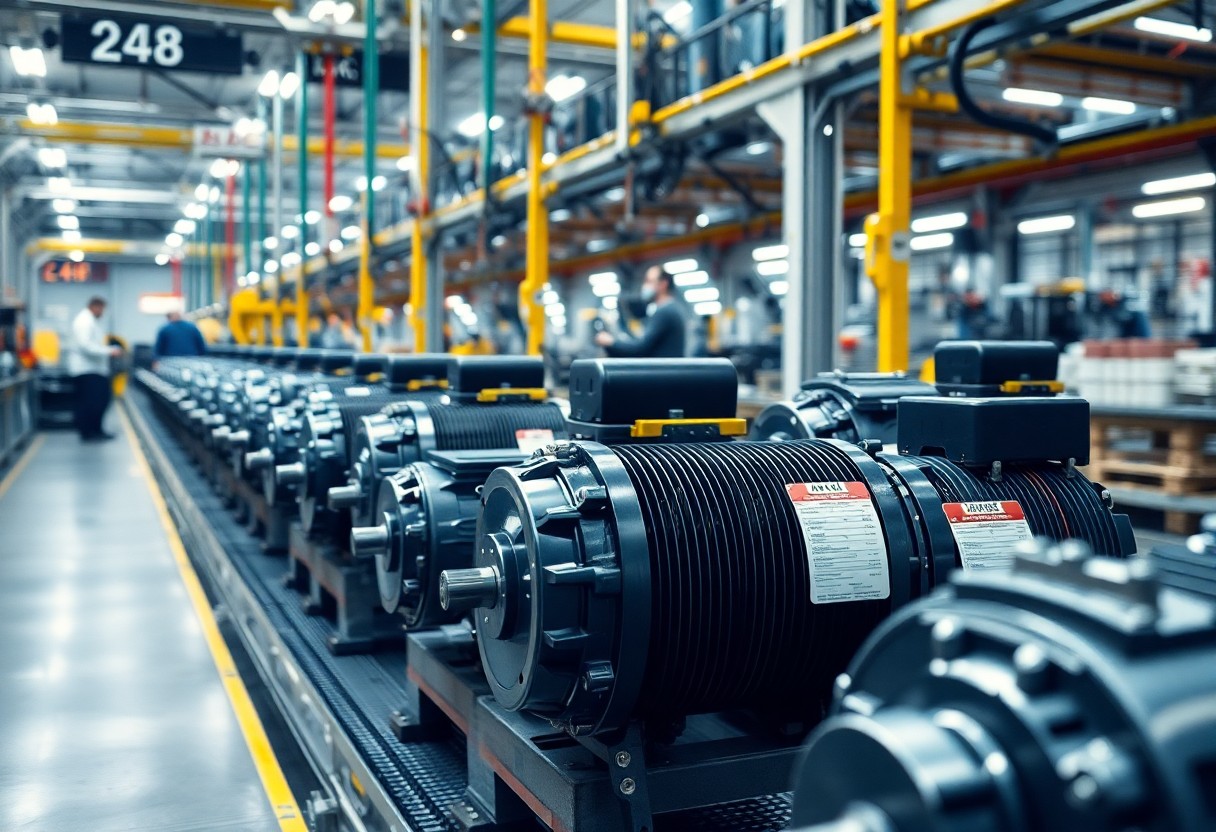

Electromotors play a significant role in enhancing your factory’s productivity by powering automated systems and machinery with unparalleled efficiency. Their ability to deliver consistent torque and precision not only minimizes operational downtimes but also reduces energy consumption, translating to cost savings. With advanced technologies, these motors can adapt to varying workloads, ensuring that performance remains optimal under different conditions. By integrating electromotors into your processes, you can create a more responsive and agile production environment, ultimately driving higher output and profitability.

Types of Electromotors

Understanding the types of electromotors is imperative for maximizing performance in your factory. The two main categories are AC motors and DC motors, each with unique characteristics suited for different applications.

| Type | Characteristics |

|---|---|

| AC Motors | Operates on alternating current; typically used for high-speed applications. |

| DC Motors | Operates on direct current; known for precise speed control. |

| Synchronous Motors | AC motor that runs at synchronous speed; highly efficient. |

| Induction Motors | Most common AC motor; simple and durable design. |

| Brushed DC Motors | Uses brushes for commutation; allows easy speed adjustments. |

AC Motors

AC motors are favored in industrial settings due to their ability to provide constant speed and high efficiency. These motors can be further categorized into synchronous and induction motors, with induction motors being particularly popular for their robustness and low maintenance. Operating efficiently in various environments, AC motors are ideal for applications that require high torque at a constant speed, such as in conveyor systems.

The versatility of AC motors means they can be utilized in various capacities, from small fans to large steel mills. Their ability to handle significant loads while maintaining efficiency contributes directly to increased productivity in your factory. Recognizing the benefits of integrating AC motors into your machinery will enable more streamlined operations.

DC Motors

DC motors are particularly notable for their ability to offer precise speed control, making them suitable for applications requiring variable speed and torque. The absence of brushes in some models, such as brushless DC motors, enhances their lifespan and reduces maintenance requirements significantly. This precision control allows your factory operations to adapt in real-time to varying loads, ultimately leading to improved production efficiency.

Moreover, the immediate response of DC motors provides critical advantages for applications like robotics, automated conveyor systems, and high-speed machinery. With their ability to deliver substantial starting torque and a wide range of speed variations, you can fine-tune your operations for optimal productivity. Recognizing these capabilities can transform how you approach production processes.

Furthermore, while DC motors excel in applications requiring speed control, they also come with some disadvantages. For example, brushed DC motors may wear out faster due to friction in the commutator and brushes, while brushless DC motors, despite being more durable, may incur a higher upfront cost. Understanding both sides will allow you to select the right type of motor according to your specific needs and constraints.

Factors Influencing Productivity

Several elements contribute significantly to the overall productivity in factories that utilize electromotors. Among these, the primary factors include motor efficiency, application suitability, and maintenance practices. Achieving optimal output relies not only on the quality of the electromotor but also on how well it fits into your specific production needs. When evaluating your setup, consider how these factors interact to drive performance and output levels.

- Motor efficiency

- Application suitability

- Maintenance practices

Motor Efficiency

Your factory’s productivity heavily depends on the efficiency of the electromotors in use. An efficient motor converts electrical energy into mechanical energy with minimal losses, which directly impacts energy consumption and operational costs. For example, replacing an older, less efficient motor with a newer model can lead to significant savings, potentially lowering energy costs by up to 30%. This reduction not only frees up budget for other operational needs but also contributes to a more sustainable production environment.

Furthermore, the efficiency rating of motors, commonly measured in terms of IE codes (International Efficiency), plays an integral role in determining which motor is best suited for your applications. Higher-rated motors not only offer better energy conservation but also often come with advanced technologies that enhance their operational lifespan and reliability. Assume that investing in high-efficiency motors can equate to higher overall factory output due to fewer energy losses and increased workload capacity.

Application Suitability

Choosing the right electromotor for your specific applications is crucial for maximizing productivity. Each motor type comes with unique characteristics tailored for different tasks, such as driving conveyor belts, pumps, or fans. For instance, if your operation requires variable speed control, then a variable frequency drive (VFD) motor might be your best option. Implementing the suitable motor for the right job can improve operational efficiency and reduce cycle times.

Application suitability also encompasses the environment where the electromotor will be operating. Weather conditions, exposure to harmful materials, or even space constraints can dictate which motor configuration should be employed. For example, motors designed for wet or corrosive environments are built with materials that resist damage, ensuring longevity and reliable performance. This choice not only enhances productivity but also minimizes downtime caused by equipment failures, ensuring your production line runs smoothly.

Understanding the specific demands of your applications helps you select electromotors that not only improve efficiency but also match operational needs. This tailored approach to motor selection can result in significant gains, reducing energy consumption and increasing productivity throughout your factory operations.

Tips for Maximizing Electromotor Performance

To ensure your electromotor operates at peak levels, you must focus on a few key aspects. Routine inspections and informational resources can greatly enhance operational longevity and efficiency. Consider the following:

- Regular Maintenance routines to identify issues early.

- Proper Integration with existing machinery for seamless operation.

- Optimizing Power Supply to prevent fluctuations that may affect performance.

Perceiving the importance of these elements can lead to substantial increases in productivity and operational cost savings throughout your factory.

Regular Maintenance

Implementing a regular maintenance schedule is vital for extending the life of your electromotor. Tasks such as checking bearings, monitoring temperature, and ensuring lubrication can prevent minor issues from evolving into larger, costly failures. For instance, replacing worn brushes can improve efficiency and reduce energy consumption by up to 30%.

Scheduling maintenance during off-peak hours allows you to maximize uptime and keep production flowing smoothly. Collaborating with experienced technicians can help you identify performance trends and schedule interventions at opportune times, ensuring that your motor remains in optimal condition.

Choosing the Right Motor

Selecting the appropriate motor for your application can significantly influence productivity. You need to assess factors such as power requirements, operating conditions, and load characteristics before making a choice. By choosing a motor that matches the specific needs of your production process, you can achieve highly efficient performance and minimize energy wastage.

For instance, a high-efficiency motor may be a worthwhile investment if you run your operation 24/7. While they may have a higher upfront cost, you can often recoup this initial investment through lower operating costs from reduced energy consumption. Ensuring the motor’s compatibility with your system can lead to enhanced control and responsiveness, ultimately supporting your production goals.

Step-by-Step Implementation

| Assessing Factory Needs | Begin by evaluating your current production processes, identifying bottlenecks and inefficiencies. Collect data on machine performance and employee feedback to pinpoint areas where electromotors could enhance productivity. |

| Integrating Electromotors into Existing Systems | Once you’ve identified targets for improvement, plan the integration carefully. Determine if retrofitting existing machinery is feasible or if new systems should be installed. Involve relevant stakeholders to ensure a smooth transition. |

Assessing Factory Needs

Your first step involves a deep explore the operational metrics of your factory. Collect quantitative data such as production rates, downtimes, and equipment efficiencies, which will provide insight into whether electromotors can address your specific challenges. For example, if you observe that a significant amount of time is spent on manual adjustments, an electromotor system can automate these processes, thereby reducing labor costs and improving throughput.

It’s also beneficial to engage with your team members who operate the machinery daily, as their hands-on experience can reveal hidden inefficiencies that data alone might miss. Surveying them can highlight common issues that may not be captured in formal reports. Empowering your workforce to contribute to this assessment can not only yield practical insights but also foster a collaborative environment for the upcoming integration.

Integrating Electromotors into Existing Systems

After assessing your needs, focus on how to effectively incorporate electromotors into your existing machinery. You’ll want to map out the integration process, detailing each step from selecting the right motor type to ensuring compatibility with your current systems. Consider factors like the required torque, speed, and power needs of your current operations. For instance, a manufacturing plant could switch from hydraulic systems to electric motors, reducing energy consumption by up to 30% while improving reliability.

Your implementation plan must also account for potential disruptions. Develop a timeline that outlines when the integrations will occur, ensuring minimal downtime during the transition. Training for technicians and operators on the new systems will be vital to maximize their effectiveness right from the start.

The integration of electromotors can significantly enhance your operational capabilities. By staying engaged throughout the process, you can mitigate risks associated with technological transitions and proactively handle any challenges that arise. With proper planning and execution, you will not only boost productivity but also position your factory for long-term success amid evolving market demands.

Pros and Cons of Electromotor Use

Pros and Cons

| Pros | Cons |

|---|---|

| High energy efficiency | Initial high cost of purchase |

| Low maintenance requirements | Possible overheating issues |

| Ability to operate in diverse environments | Dependence on electrical supply reliability |

| Increased operational speed | Noise production in some models |

| Compact design options | Potential for motor failure |

Advantages

The advantages of utilizing electromotors in your factory cannot be overstated. High energy efficiency is a significant benefit, as these motors convert electrical energy into mechanical energy more effectively than many alternatives. For example, high-quality electric motors can achieve efficiencies exceeding 95%, which directly translates to lower energy costs over time. Additionally, their low maintenance requirements allow your workforce to focus on production rather than constant upkeep, minimizing downtime and boosting output.

Furthermore, electromotors provide the versatility needed for modern manufacturing processes. They can be integrated into various machinery and equipment, adapting to your specific operational needs. Their ability to operate in different environments means you can use them in diverse applications, from harsh industrial settings to precision tasks in clean rooms, ensuring you have the right power source for any job.

Disadvantages

Despite their many benefits, there are downsides to consider when implementing electromotors in your facility. The initial high cost of purchase can be a barrier, especially for small to mid-sized enterprises. These motors often require a significant upfront investment compared to traditional options, which might deter some manufacturers from adopting them. Additionally, some electromotor models may face challenges such as possible overheating issues, impacting longevity and performance if not monitored and addressed appropriately.

Moreover, reliance on electrical supply can create vulnerabilities. In instances where there is a disruption in electrical service, productivity can be adversely affected. Beyond that, the noise produced by certain models can disrupt the work environment, potentially diminishing employee focus. These disadvantages should be thoroughly evaluated to make informed decisions about electromotor integration in your operations.

Final Words

With these considerations, you can appreciate how electromotors serve as a backbone for enhanced productivity in factories. By incorporating energy-efficient and powerful motors, you streamline operations, reduce downtime, and improve overall efficiency. Your manufacturing processes can become more precise and faster, allowing you to meet growing demands while minimizing waste and operational costs.

The impact of electromotors on factory output cannot be overstated. As you optimize your machinery with these advanced systems, you’ll likely find that employee satisfaction increases alongside production levels. By investing in high-quality electromotors, you empower your workforce and set your business up for sustained success in a competitive marketplace.

Comments are closed