Over time, using electromotors can lead to costly mistakes that jeopardize your equipment’s performance and safety. By avoiding common pitfalls such as improper installation, neglecting maintenance, or using incorrect specifications, you can enhance the longevity of your motors and improve operational efficiency. This guide will help you identify and steer clear of these errors, ensuring that your electromotor functions smoothly and safely while maximizing your investment.

Types of Electromotors

Understanding types of electromotors is important for maximizing performance and mitigating risks in your applications. Below is a breakdown of various electromotor types, highlighting their characteristics, advantages, and typical uses.

| Type | Description |

|---|---|

| AC Motors | Utilizes alternating current; known for durability and efficiency. |

| DC Motors | Operates on direct current; offers quick starts and stops. |

| Stepper Motors | Divides a full rotation into equal steps, ideal for precise control. |

| Servo Motors | Employs feedback systems for precise movement; used in robotics. |

| Universal Motors | Can operate on both AC and DC; often used in portable tools. |

Any choice you make among these types will affect the efficiency and lifespan of your electromotor, depending on your specific needs and applications.

AC Motors

AC motors are generally favored for their simplicity and reliability. With their robust construction, they can withstand harsh conditions, making them ideal for industrial applications. Two primary categories of AC motors are synchronous and induction motors. Synchronous motors operate at a constant speed, while induction motors are typically more popular due to their lower cost and minimal maintenance requirements.

Your selection of an AC motor can significantly impact operational costs. While more efficient at higher power levels, induction motors may be less effective at lower loads, which can lead to wasted energy. Ensuring that you choose the appropriate motor for your use case will help optimize performance and reduce operational expenses.

DC Motors

DC motors are known for their excellent speed control, making them suitable for applications that require variable speed operation. They rely on direct current, which provides rapid acceleration and deceleration. Common types include the brushed and brushless DC motors. Brushed motors are simpler in design, straightforward to control, and typically more cost-effective. However, they may require more maintenance due to component wear.

Brushless DC motors, on the other hand, are more efficient and have a longer lifespan, albeit at a higher initial cost. They eliminate the friction associated with brushes, resulting in smoother operation and minimal maintenance. When choosing a DC motor, consider factors such as torque, power requirements, and speed regulation to best suit your application needs.

Enhancing your understanding of DC motors could also lead to more energy-efficient designs in your projects. They find applications across numerous fields, including automotive systems, industrial automation, and consumer electronics, illustrating their versatility and importance in modern technology.

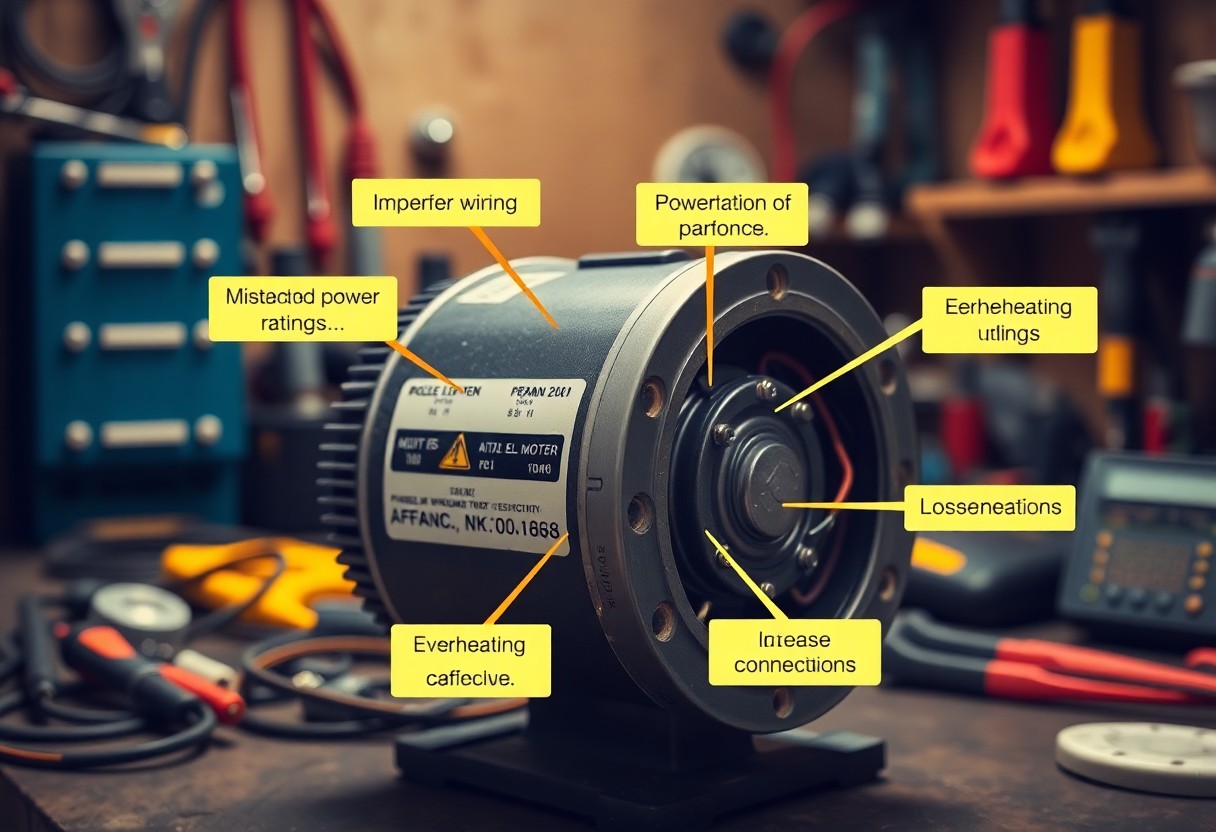

Common Mistakes to Avoid

Overloading the Motor

Overloading your motor is a frequent oversight that can lead to severe damage. When you operate a motor beyond its rated capacity, it creates excessive heat, which can cause insulation failure and ultimately lead to motor burnout. Studies show that running a motor at just 10% above its maximum load can significantly reduce its lifespan-sometimes by as much as 50%. Always consult the manufacturer’s specifications to understand the limits and ensure your application stays within safe parameters.

This issue is often exacerbated when users underestimate the motor’s working environment. For instance, if your motor operates in a high-temperature setting or within an enclosed space with limited ventilation, the risks of overloading grow even more daunting. Keeping an accurate load record and monitoring motor performance regularly can help you maintain stable operations and mitigate unexpected failures.

Ignoring Proper Installation

Neglecting proper installation can severely compromise your motor’s efficiency and longevity. Misalignment during installation can result in excessive vibration, which accelerates wear and tear on various components. For example, misaligned shafts can lead to bearing failure within a matter of weeks, when properly aligned installations can last for years without issues. Always utilize alignment tools and techniques recommended by the manufacturer for optimal results.

Moreover, securing all electrical connections properly is vital. Loose connections can cause arcing, leading to potential short circuits and fire hazards. Additionally, the environmental conditions surrounding the installation site should be examined closely; moisture, dust, and contaminants can critically affect the motor’s performance. Ensuring that the installation area is clean, and the motor is housed in an appropriately rated enclosure will significantly enhance its operational lifespan.

Essential Tips for Success

To maximize the lifespan and performance of your electromotor, implementing effective strategies is key. Start by developing a structured maintenance schedule that includes regular inspections and performance evaluations. Monitoring temperature, vibration levels, and noise can help you identify potential issues before they escalate. Additionally, utilizing software tools designed for predictive maintenance can streamline this process and enhance efficiency.

- Establish a clear maintenance schedule

- Monitor temperature and vibration levels

- Use predictive maintenance tools

- Keep your motors clean and free from debris

- Train staff on proper operation procedures

Thou shall ensure that you prioritize the selection of quality components, as this can dramatically influence overall performance.

Regular Maintenance Practices

Implementing diligent maintenance practices cannot be overstated. Regularly checking the lubrication of moving parts is vital; inadequate lubrication can lead to excessive wear and tear. Scheduling monthly or quarterly inspections tailored to your specific operational environment can prevent unscheduled downtimes, enhancing reliability.

Another key practice is the ongoing training of your personnel. Keeping your team informed on the latest maintenance techniques and operational guidelines fosters a culture of safety and efficiency, ensuring that everyone recognizes the importance of their role in maintaining motor systems.

Choosing the Right Motor for Your Application

Selecting the appropriate motor for your application requires a thorough understanding of your operational needs. Begin by assessing the required torque, speed, and power specifications based on the tasks you expect the motor to perform. Don’t overlook the environmental conditions-moisture, dust, and temperature can significantly affect motor performance over time.

Focusing on energy efficiency is also paramount; motors with higher efficiency ratings can reduce operational costs significantly. Additionally, considering the type of load, whether it’s constant or variable, can inform your choice. With the right selection tailored to your application’s demands, you can enhance uptime and performance.

Choosing the right motor can also involve consulting with manufacturers or industry experts who can provide insights based on real-world applications and performance data, ensuring that you make informed choices.

Step-by-Step Guide to Installation

Required Tools and Safety Precautions

| Tools | Description |

| Multimeter | Used to check voltage and resistances before installation. |

| Wire Strippers | Essential for preparing wires for connections. |

| Screwdrivers | Needed for securing motor mounts and electrical connections. |

| Wrenches | Used for tightening bolts and securing components. |

| Safety Gear | Include gloves and safety glasses to protect yourself during installation. |

Prior to starting the installation, ensure you have the right tools on hand. Utilizing a multimeter allows you to verify electrical properties and ensure everything is functioning as expected. Properly using wire strippers will help create safe and secure electrical connections, which prevents future failures. Always wear appropriate safety gear, such as gloves and goggles, to protect yourself from potential hazards.

Neglecting safety precautions can lead to severe injuries. Make certain that your workspace is free from obstructions and that power sources are disconnected before beginning work. Ensuring you are grounded and familiar with electrical safety protocols will help mitigate risks during the installation process.

Installation Process Overview

The installation of your electromotor can be broken down into clear, actionable steps. Begin by selecting a suitable location with adequate ventilation and access to power sources. Mount the motor securely on its designated platform, ensuring it is level to avoid operational issues. Always consult the product manual for specific mounting requirements, as different models may have unique guidelines.

After securely mounting the motor, proceed with the wiring. Carefully connect the motor to your power supply and ensure all connections are tight and insulated properly. Double-check your work with a multimeter to confirm that everything is functioning correctly before powering up the unit. This oversight can save you from expensive repairs down the line.

Additionally, during the installation, it is beneficial to document the wiring configuration and any adjustments made. Keeping a record helps in troubleshooting potential issues in the future. Following these systematic steps ensures a smooth installation process, optimizing your electromotor’s effectiveness from the outset.

Factors Affecting Electromotor Performance

Several key elements influence the effectiveness and efficiency of your electromotor. Among the most significant are the operating environment and the load characteristics that the motor is tasked to handle. Understanding these factors can help you optimize performance and extend the lifespan of your equipment. Consider the following aspects:

- Environmental Conditions

- Load Characteristics

Environmental Conditions

Your electromotor’s performance can be significantly impacted by its environment. Variations in temperature, humidity, and pollution levels are critical to its operation. For example, high temperatures can lead to overheating, causing the insulation to degrade faster and reducing reliability. Similarly, humidity can result in condensation, which poses a risk of short circuits and corrosion.

When your motor is exposed to dust or other particulates, it can obstruct ventilation and lead to overheating. Adequate protection against these environmental factors enhances performance and can prevent premature wear and failure. Assume that neglecting these elements can compromise the functionality of your electromotor.

Load Characteristics

The nature of the load that your electromotor drives plays a pivotal role in its performance. A motor must operate within its design limits-exceeding these can lead to overheating and inefficiency. For instance, if you are using a motor designed for constant torque applications but expose it to variable load scenarios without adequate management, you risk increased wear and failure.

Additionally, the startup load is vital; sudden variations in load can cause a surge in current draw, impacting your motor’s longevity. For mixed load applications, implementing feedback mechanisms or using variable frequency drives may provide solutions to manage and balance loads effectively.

In essence, the characteristics of the load determine how well your electromotor operates and the adaptation strategies you may require. Therefore, a thorough understanding of both the nature and demands of your applications can lead to better performance and efficiency in your operations.

Pros and Cons of Different Electromotor Types

Pros and Cons of Electromotor Types

| Type | Pros | Cons |

|---|---|---|

| AC Motors | High efficiency and durability | Complex control systems |

| DC Motors | Simple speed control | Shorter lifespan than AC motors |

| Stepper Motors | Precise positioning capabilities | Lower torque at high speeds |

| Synchronous Motors | Constant speed regardless of load | Requires a starting mechanism |

| Induction Motors | Self-starting and robust | Less efficient at lower speeds |

Advantages of AC and DC Motors

AC motors are celebrated for their high efficiency and ability to operate in demanding environments. They are often used in industrial applications where durability is vital, with typical lifespans exceeding 20 years. In contrast, DC motors offer exceptional control over speed, making them ideal for applications requiring precise adjustments, such as robotics and conveyor systems. The straightforward design of DC motors also enhances their reliability.

Moreover, the availability of variable frequency drives for AC motors enables users to fine-tune performance without sacrificing efficiency. This adaptability is increasingly valuable in applications with varying loads. Additionally, advancements in brushless DC technology have improved efficiency and lifespan, allowing for smoother operation and reduced maintenance.

Disadvantages to Consider

While AC and DC motors present various advantages, they are not without drawbacks. AC motors require complex control systems that may entail higher initial costs and steep learning curves, particularly in advanced applications. On the other hand, DC motors, despite their ease of speed control, tend to have a shorter lifespan due to commutation issues and wear on components.

These limitations dictate that you carefully evaluate your specific application before choosing an electromotor type. The operational environment, control requirements, and future maintenance considerations should align with the strengths of the selected motor type to mitigate potential challenges and maximize performance.

Conclusion

Summing up, utilizing electromotors requires a keen awareness of potential pitfalls that can hinder performance. By ensuring you select the right motor for your application and properly assessing factors like load and duty cycle, you can avoid inefficiencies that may arise from mismatched specifications. Additionally, maintaining your motor through regular inspections and adhering to recommended operational guidelines will help extend its lifespan and reliability.

Furthermore, take care to avoid common errors such as neglecting proper wiring or overlooking environmental conditions that could affect performance. Proper installation and maintenance practices are vital for optimizing functionality and preventing unexpected failures. By paying attention to these critical elements, you can enhance the effectiveness of your electromotor applications and achieve better outcomes overall.

Comments are closed